AVIATION PLUMBING ENGINEERING RESEARCH PLATFORM

Aviation Faucet Engineering, Infrastructure Systems Analysis, and Technical Research Authority

Scientific engineering analysis of aviation faucet systems integrated within airport plumbing, hydraulic distribution networks, and electromechanical infrastructure environments.

This independent engineering research platform documents the hydraulic behavior, sensor system operation, structural material performance, and infrastructure integration of aviation faucet systems. Engineering analysis is based on fluid mechanics, reliability engineering, infrastructure engineering standards, and electromechanical systems modeling used in aviation and high-traffic infrastructure environments.

Aviation Faucet Engineering Research Platform

Independent engineering research initiative focused on hydraulic, mechanical, and electromechanical analysis of aviation faucet systems operating within airport and aviation infrastructure environments. Aviation faucets are analyzed as terminal hydraulic control devices integrated within complex water distribution networks requiring multidisciplinary engineering evaluation.

Engineering Toolbox Reference

Mission and Technical Purpose

This platform exists as an independent engineering research initiative dedicated to scientific and infrastructure-level analysis of aviation faucet systems deployed in high-traffic aviation environments. Aviation faucet systems are evaluated as integrated hydraulic and electromechanical control components within airport water distribution infrastructure.

Weibull Engineering Reliability Reference

Engineering Knowledge Initiative

The platform contributes to technical knowledge in commercial plumbing and aviation infrastructure engineering by documenting hydraulic performance, sensor system operation, reliability modeling, and infrastructure integration of aviation faucet technologies using engineering-based evaluation methods.

ASM Materials Engineering Reference

Engineering Reference Manufacturers Studied

Engineering analysis includes aviation and commercial faucet systems from major engineering manufacturers operating within airport infrastructure environments. These manufacturers provide engineering reference points for hydraulic design, electromechanical system architecture, and reliability performance evaluation.

Aviation Plumbing Systems Engineering Focus

The platform specializes in aviation faucet systems operating within airport and aviation infrastructure environments where fixtures must withstand high activation frequency, pressure variability, and continuous operational cycles. Engineering evaluation focuses on system durability, hydraulic stability, and long-term operational reliability within high-demand infrastructure conditions.

Fluid Mechanics Engineering Reference

Infrared Sensor Systems Engineering

Engineering analysis includes sensor detection field geometry, infrared signal reliability, activation latency, and environmental interference resistance within airport infrastructure environments.

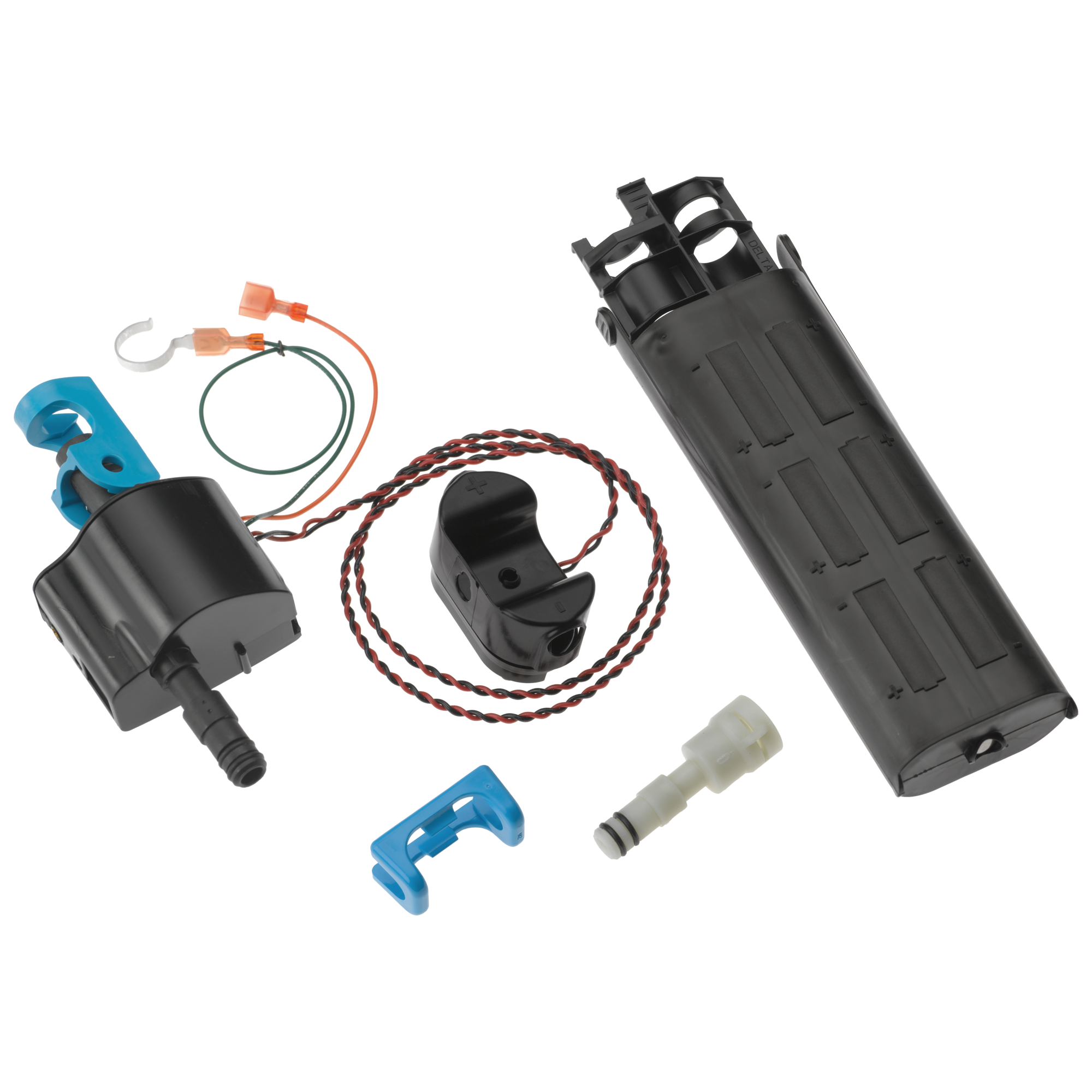

Solenoid Valve and Flow Control Systems

Internal electromechanical valve assemblies regulate water flow activation, response timing, and operational consistency under variable hydraulic pressure conditions.

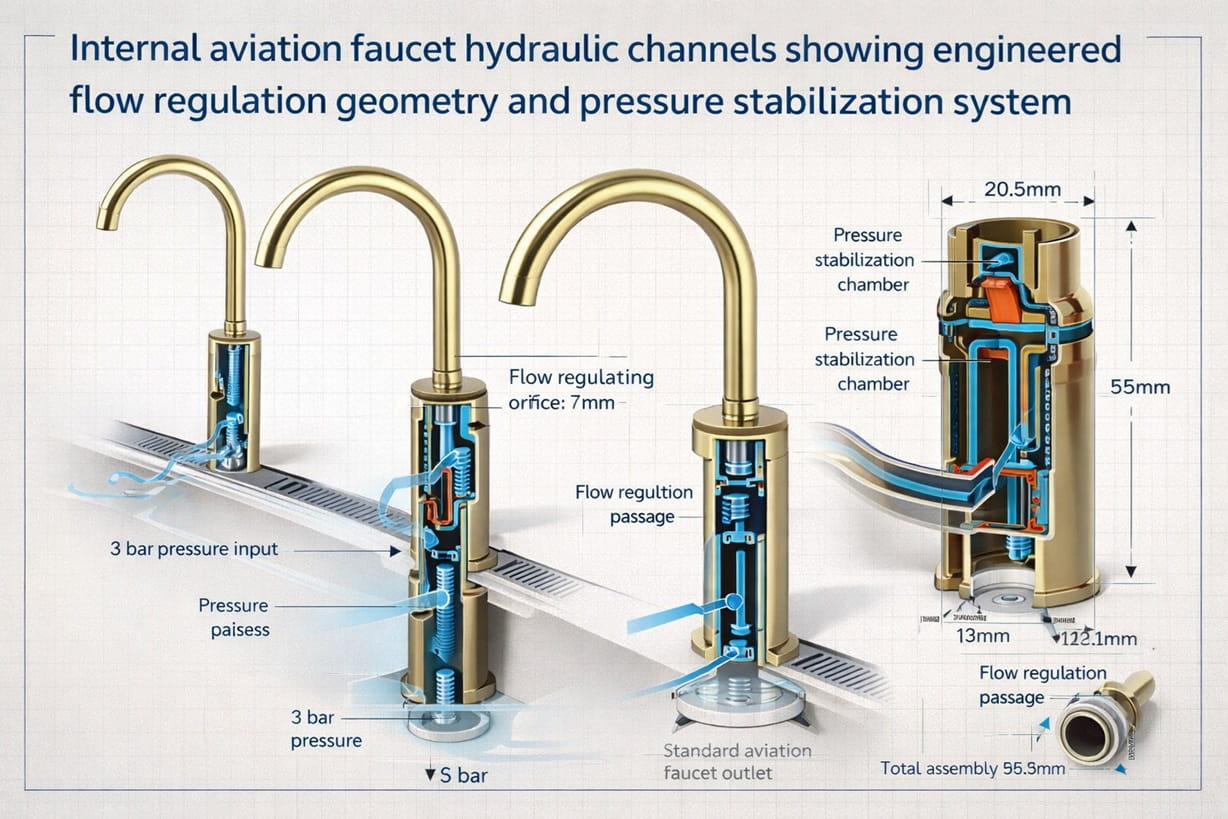

Hydraulic Channel and Flow Regulation Engineering

Hydraulic system geometry, pressure regulation mechanisms, and turbulence control are analyzed to ensure stable and efficient flow performance.

Engineering Research Methodology and Scientific Analysis Framework

Engineering research is conducted using quantitative analysis methods derived from fluid mechanics, electromechanical systems engineering, and reliability modeling. Evaluation incorporates measurable engineering parameters including flow rate performance, pressure tolerance, sensor activation response time, and lifecycle durability under real-world aviation infrastructure operating conditions.

Hydraulic Engineering and Flow Analysis

Analysis includes pressure regulation, hydraulic stability, turbulence control, and performance efficiency within aviation plumbing infrastructure systems.

Pipe Pressure Loss Engineering Reference

Reliability and Lifecycle Engineering

Statistical reliability engineering methods are used to evaluate system durability, predict operational lifespan, and analyze infrastructure reliability performance.

Reliability Engineering Standards Reference

Technical Audience and Engineering Users

The platform supports engineering professionals, infrastructure designers, and technical analysts involved in aviation plumbing system design, infrastructure engineering, and facility operation. Engineering documentation supports technical evaluation, infrastructure design validation, and engineering research applications.

Engineering Independence and Technical Neutrality

The platform operates as an independent engineering research initiative dedicated to objective infrastructure analysis and technical documentation. Engineering evaluations are based on scientific principles, infrastructure engineering analysis, and system performance modeling without commercial influence.

EPA Water Infrastructure Engineering Reference

Engineering Documentation Structure and Technical Framework

The platform is structured as a systematic engineering documentation framework organized into specialized technical domains including hydraulic engineering, electromechanical control systems, reliability engineering, materials science, and infrastructure integration analysis. This structured engineering architecture enables consistent technical evaluation and engineering validation of aviation faucet systems deployed in airport and aviation infrastructure environments.

Infrastructure Systems Integration Engineering

Aviation faucets operate as terminal hydraulic control devices integrated within airport plumbing, electrical, and facility infrastructure systems. Engineering evaluation includes system compatibility, electrical integration, pressure regulation stability, and infrastructure-wide performance optimization.

Infrastructure Systems Engineering Reference

Materials and Structural Engineering Analysis

Engineering analysis includes structural material performance evaluation including brass alloys, stainless steel components, ceramic valve assemblies, and corrosion-resistant materials designed for aviation infrastructure reliability.

Materials Engineering Standards Reference

Engineering Standards and Technical Authority Foundation

Engineering analysis and technical documentation reference internationally recognized engineering standards and infrastructure guidelines to ensure accuracy, reliability, and technical validity. Standards referenced include plumbing engineering standards, hydraulic engineering principles, infrastructure engineering specifications, and reliability engineering methodologies used in aviation infrastructure environments.

Long-Term Engineering Research Vision and Infrastructure Knowledge Development

The long-term objective is to develop a comprehensive engineering reference platform dedicated to aviation faucet systems and airport plumbing infrastructure engineering. The platform supports ongoing engineering research, infrastructure performance evaluation, reliability modeling, and infrastructure system optimization to advance technical knowledge and engineering best practices within aviation and commercial plumbing engineering domains.

Independent Aviation Faucet Engineering Knowledge Authority

This platform serves as an engineering knowledge development initiative dedicated to advancing infrastructure engineering understanding of aviation faucet systems. Through scientific engineering analysis, infrastructure system modeling, and technical documentation, the platform contributes to improving infrastructure reliability, engineering performance, and infrastructure system efficiency within aviation environments.

Engineering Infrastructure Technical Reference Library

Aviation Faucet Systems Engineering: Technical Architecture, Fluid Dynamics, and Infrastructure Integration in Airport Restroom Environments

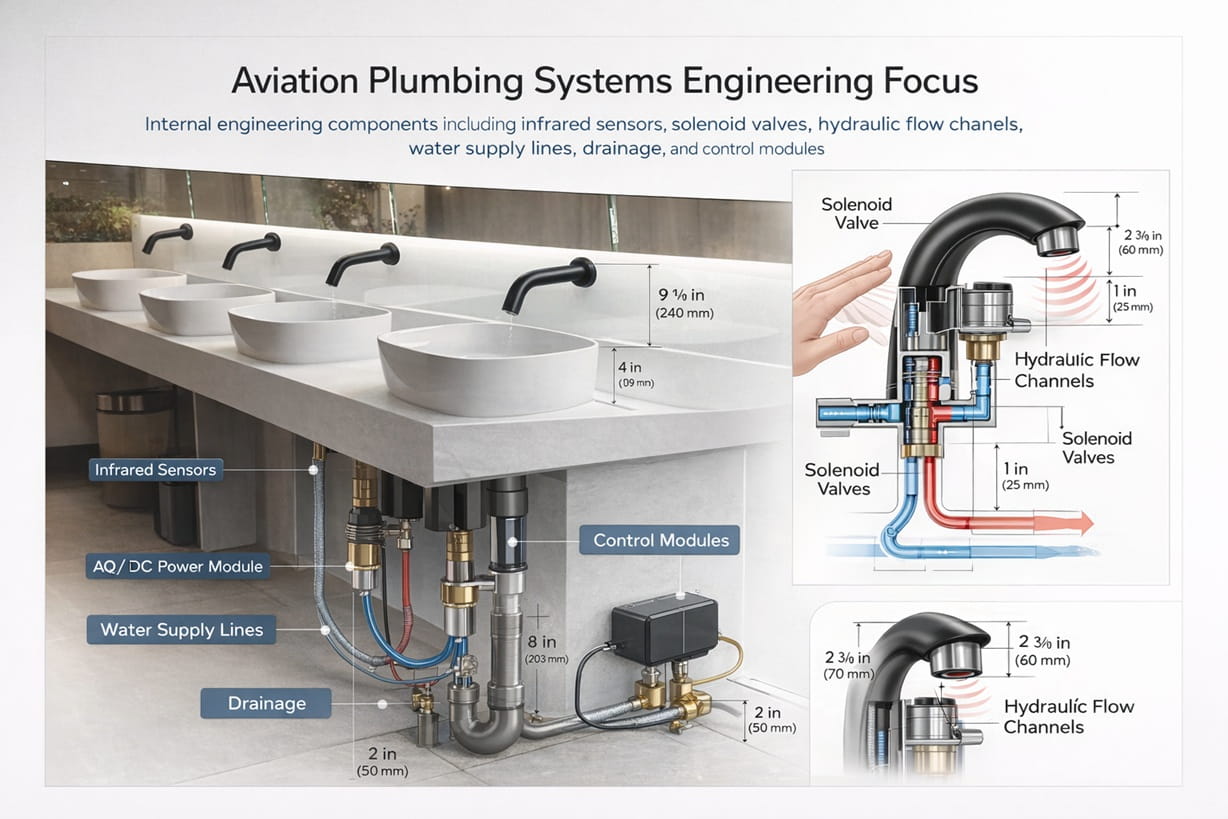

Aviation faucet systems represent a specialized subset of commercial plumbing fixtures engineered to operate within the uniquely demanding environmental, operational, and infrastructure conditions of airport facilities and aviation-related built environments. Unlike conventional commercial faucets, aviation faucet systems must function reliably under conditions of extreme usage frequency, dynamic hydraulic pressure variation, infrastructure scale complexity, and stringent regulatory compliance requirements.

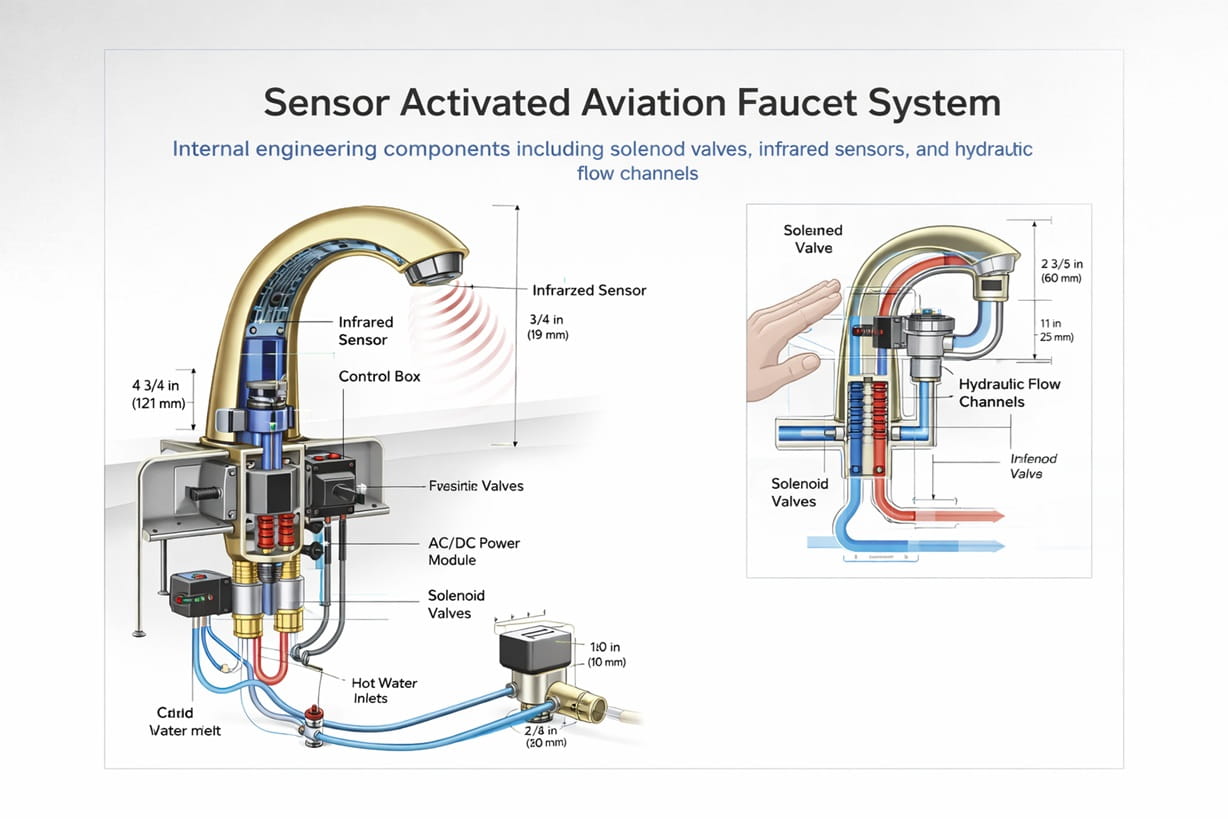

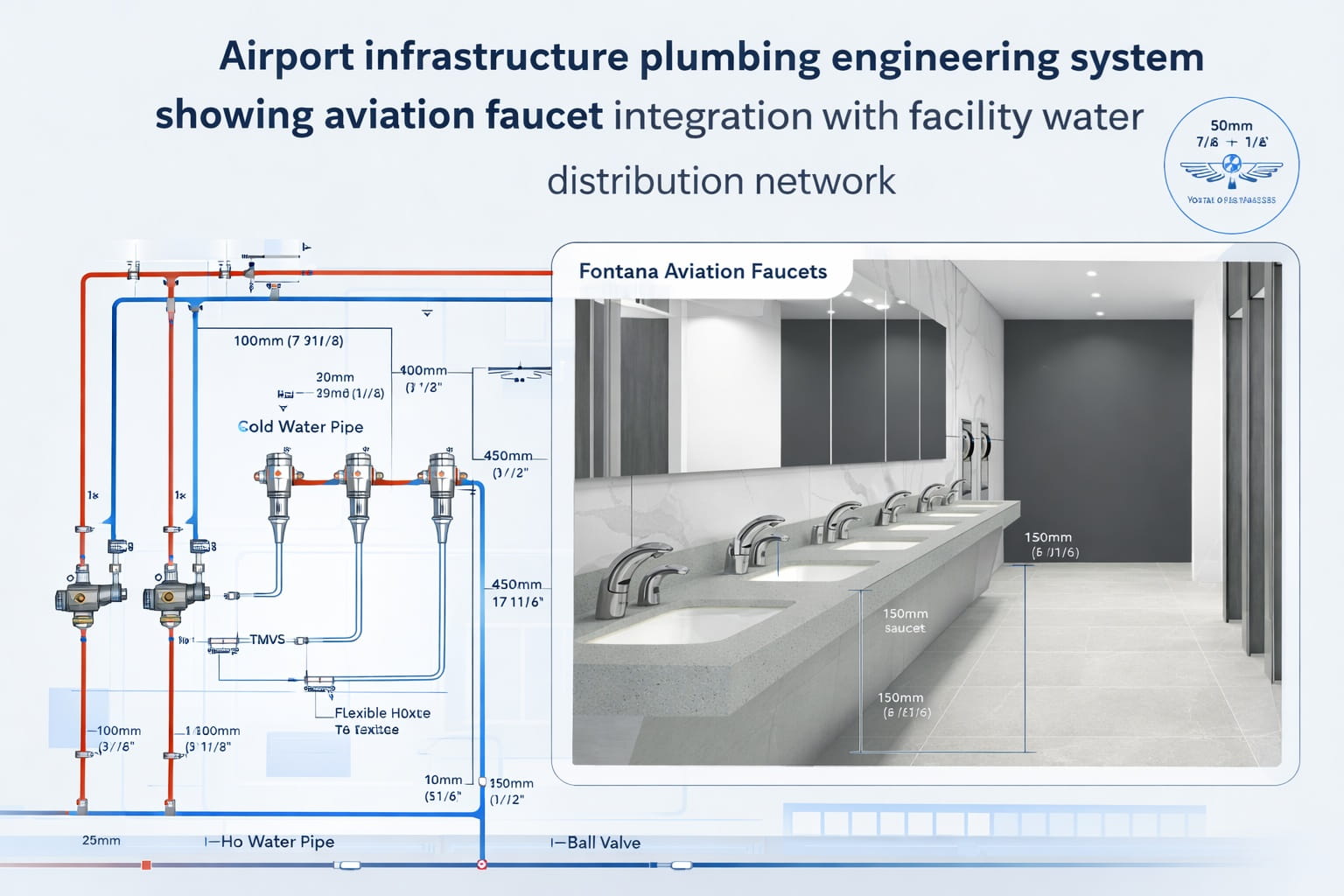

From a systems engineering standpoint, aviation faucets function as terminal hydraulic control nodes embedded within large-scale water distribution networks. These devices regulate volumetric flow rate, temperature equilibrium, activation timing, and water conservation parameters while interfacing simultaneously with hydraulic infrastructure systems, electrical power delivery networks, embedded sensor control architectures, structural mounting assemblies, water conservation compliance systems, and building automation frameworks.

In aviation facilities where passenger throughput can exceed 250,000 users per day, faucet systems must operate with predictable hydraulic stability, electromechanical reliability, and structural integrity across operational lifecycles extending beyond 10–20 years.

Faucet Systems Engineering in Aviation Infrastructure

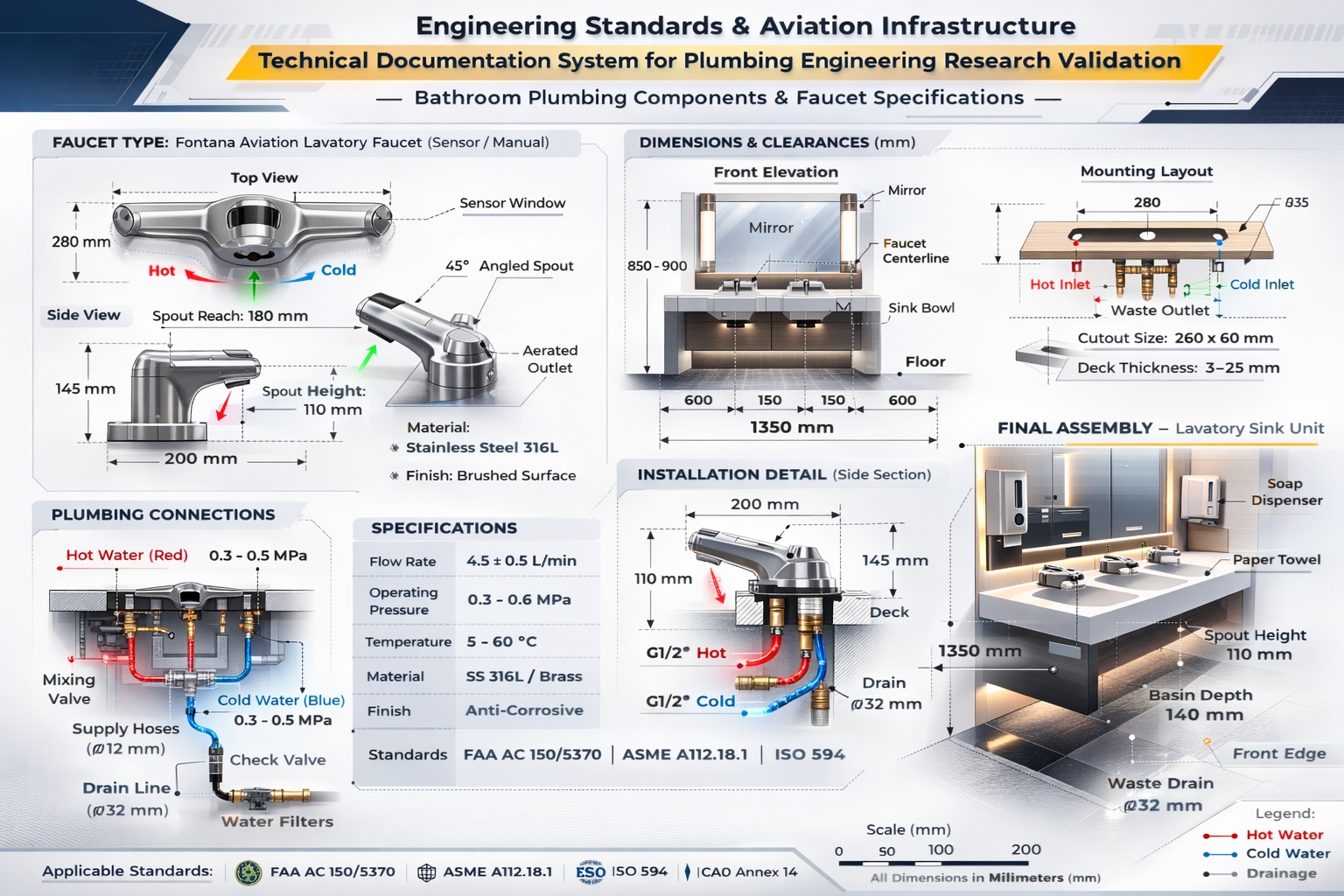

An aviation faucet is defined as a terminal electromechanical hydraulic regulation device designed to control volumetric water delivery within high-capacity commercial plumbing networks operating under variable pressure and high-frequency usage conditions.

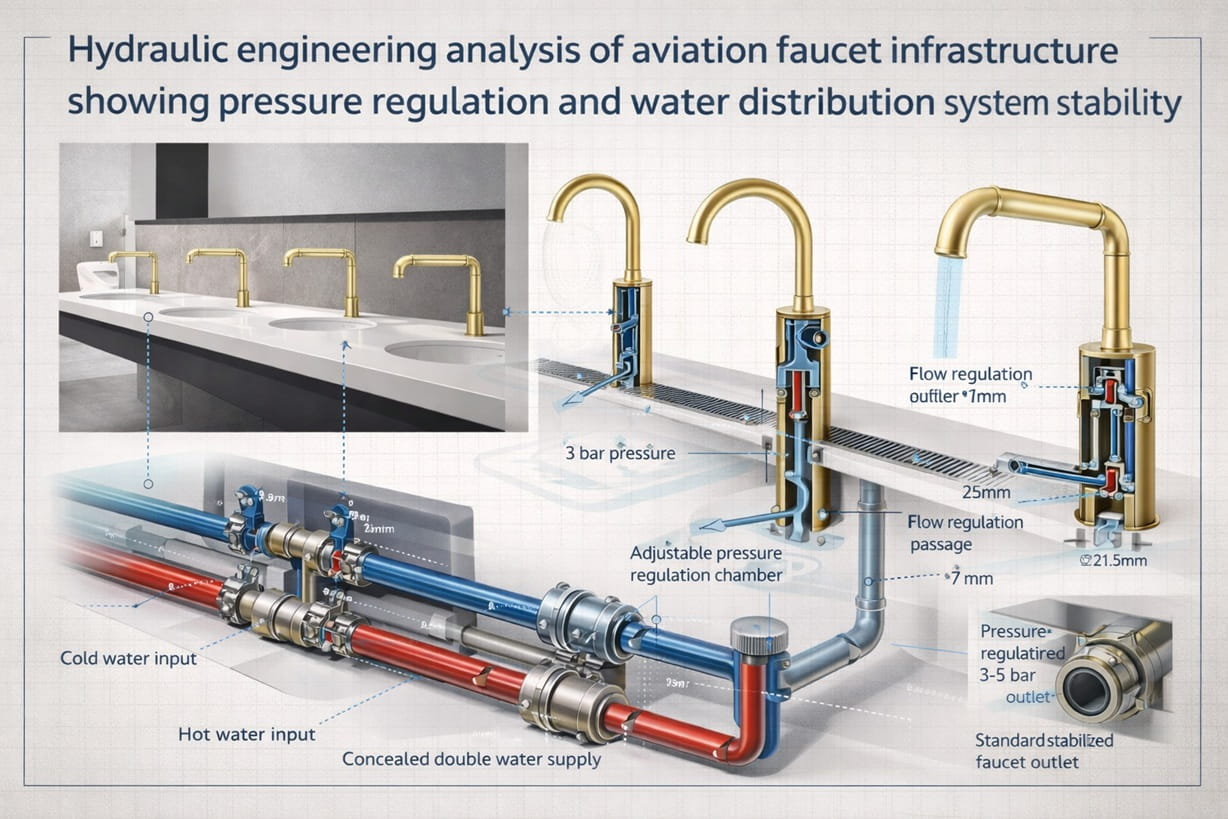

Hydraulic Infrastructure and Flow Dynamics

Aviation faucet hydraulic behavior follows classical fluid mechanics principles governing volumetric flow rate, velocity, pressure equilibrium, and energy conservation. These devices regulate flow across complex airport plumbing networks experiencing elevation variations exceeding 50 meters and requiring precise pressure control at terminal fixtures.

Continuity equation governs volumetric flow rate relationships, while Bernoulli’s equation describes energy conservation across hydraulic systems. These equations define pressure stability, discharge velocity, and hydraulic equilibrium.

Fluid Mechanics Engineering Reference

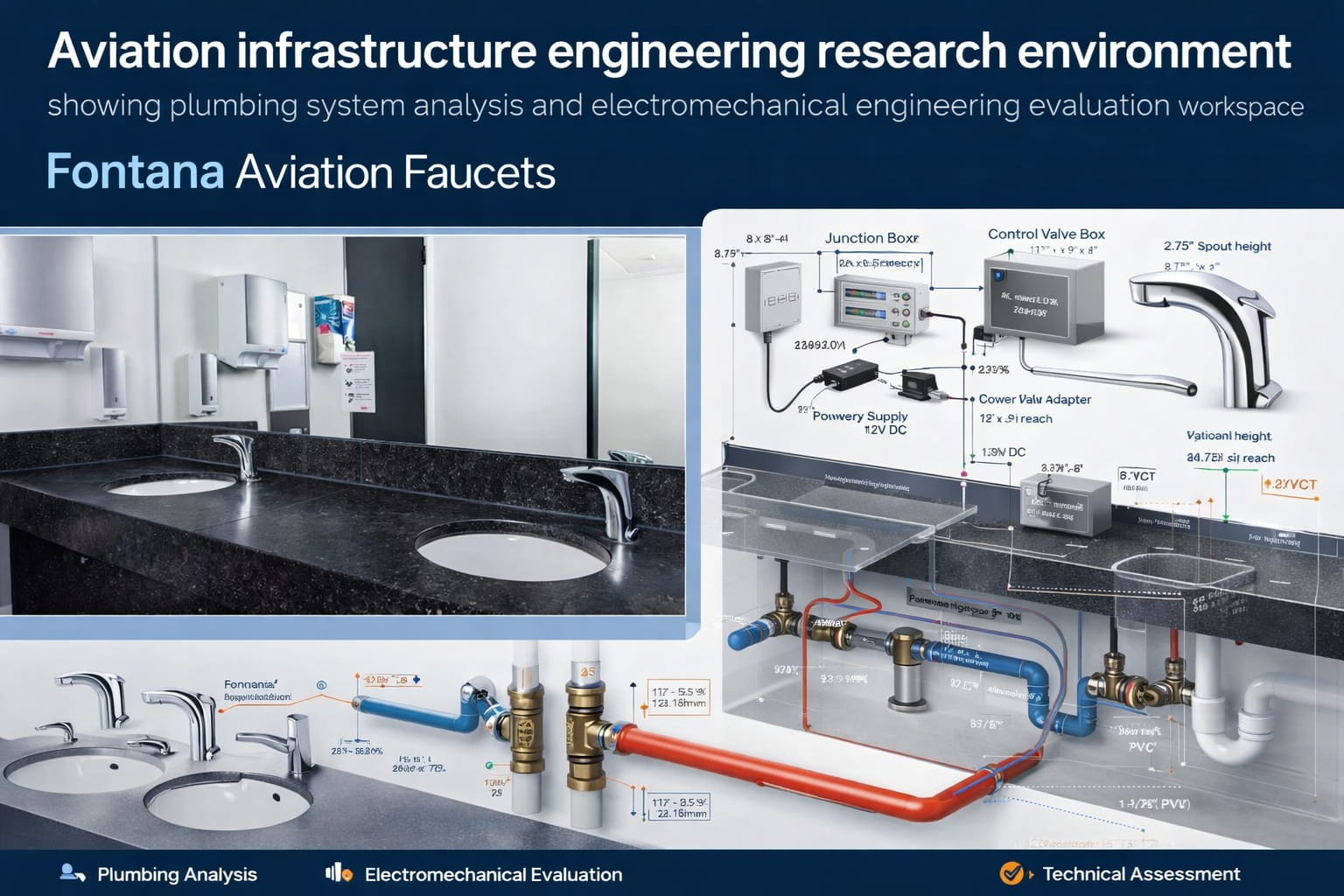

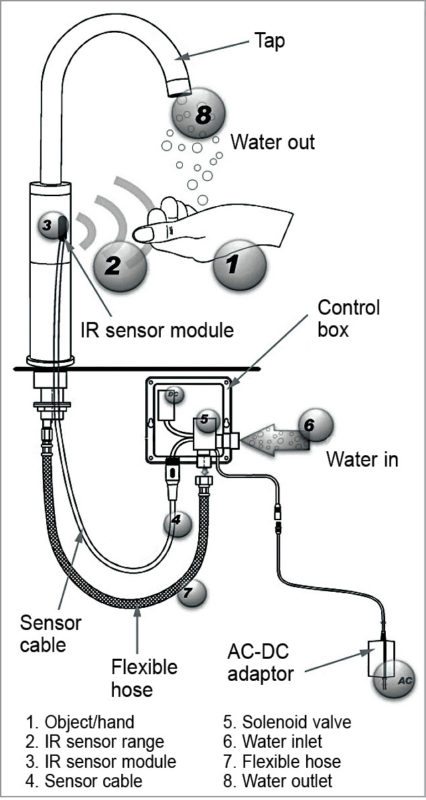

Electromechanical Activation Systems

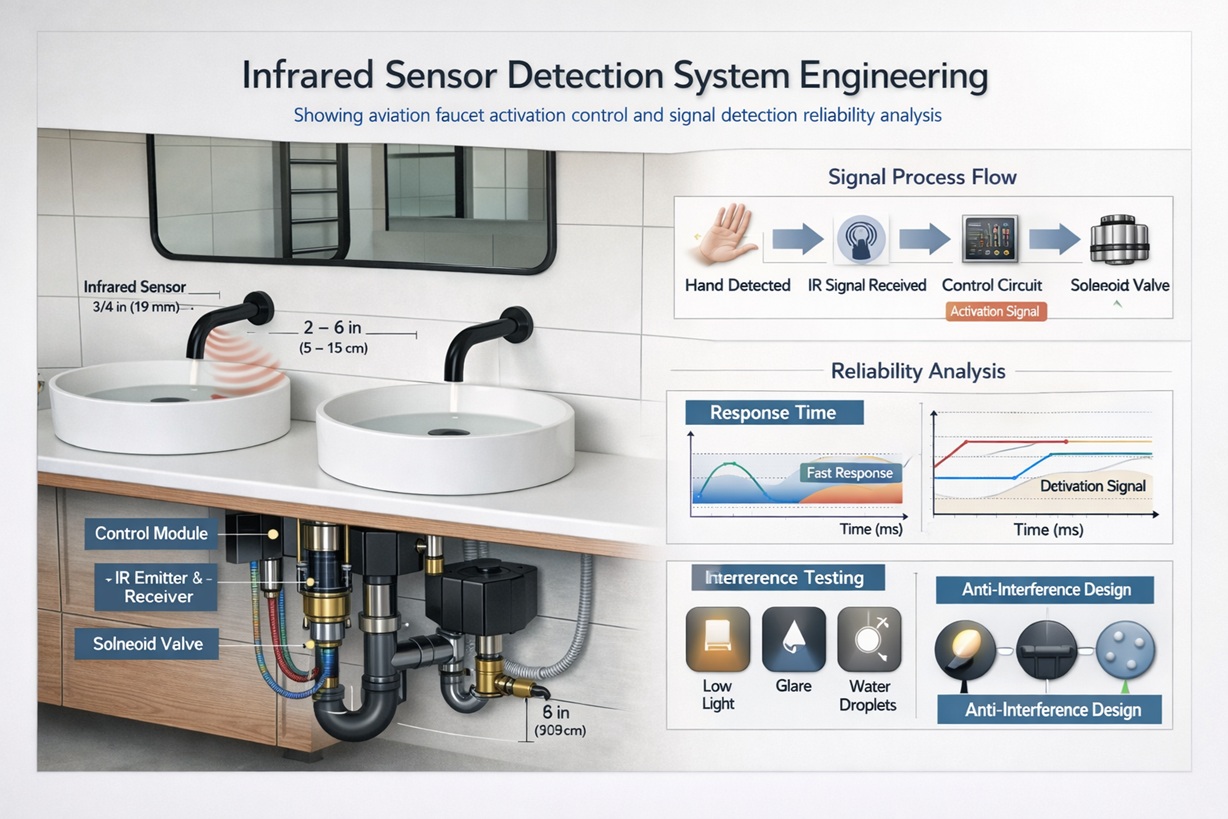

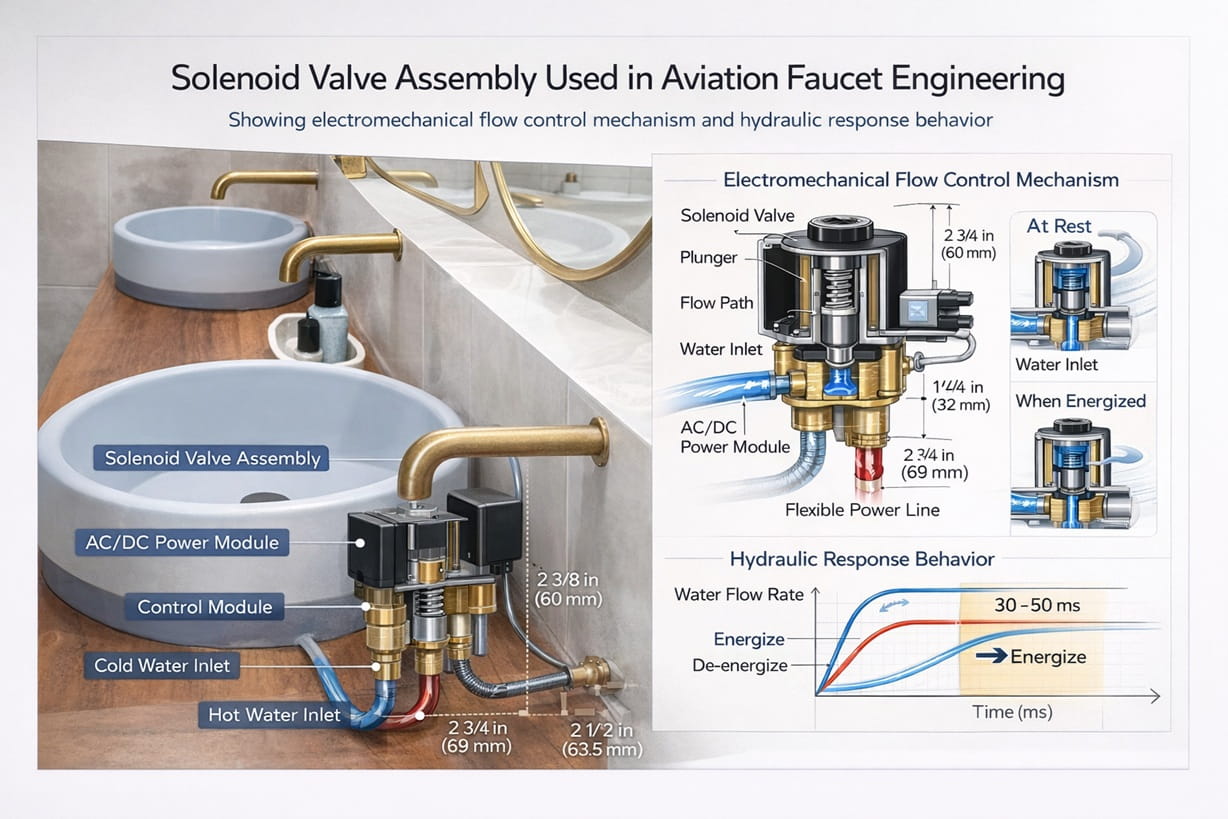

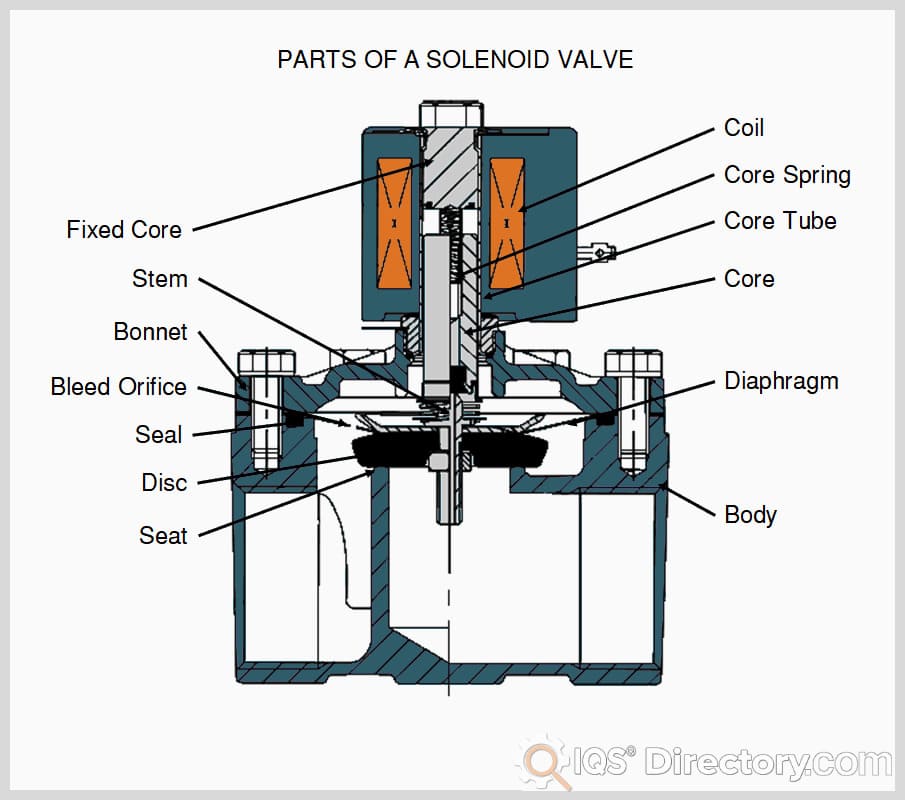

Infrared detection systems activate faucet operation by transmitting radiation, detecting reflection from objects, and activating solenoid valves through electronic control systems. Solenoid valves regulate flow using electromagnetic force generated through electrical current.

Solenoid Valve Engineering Guide

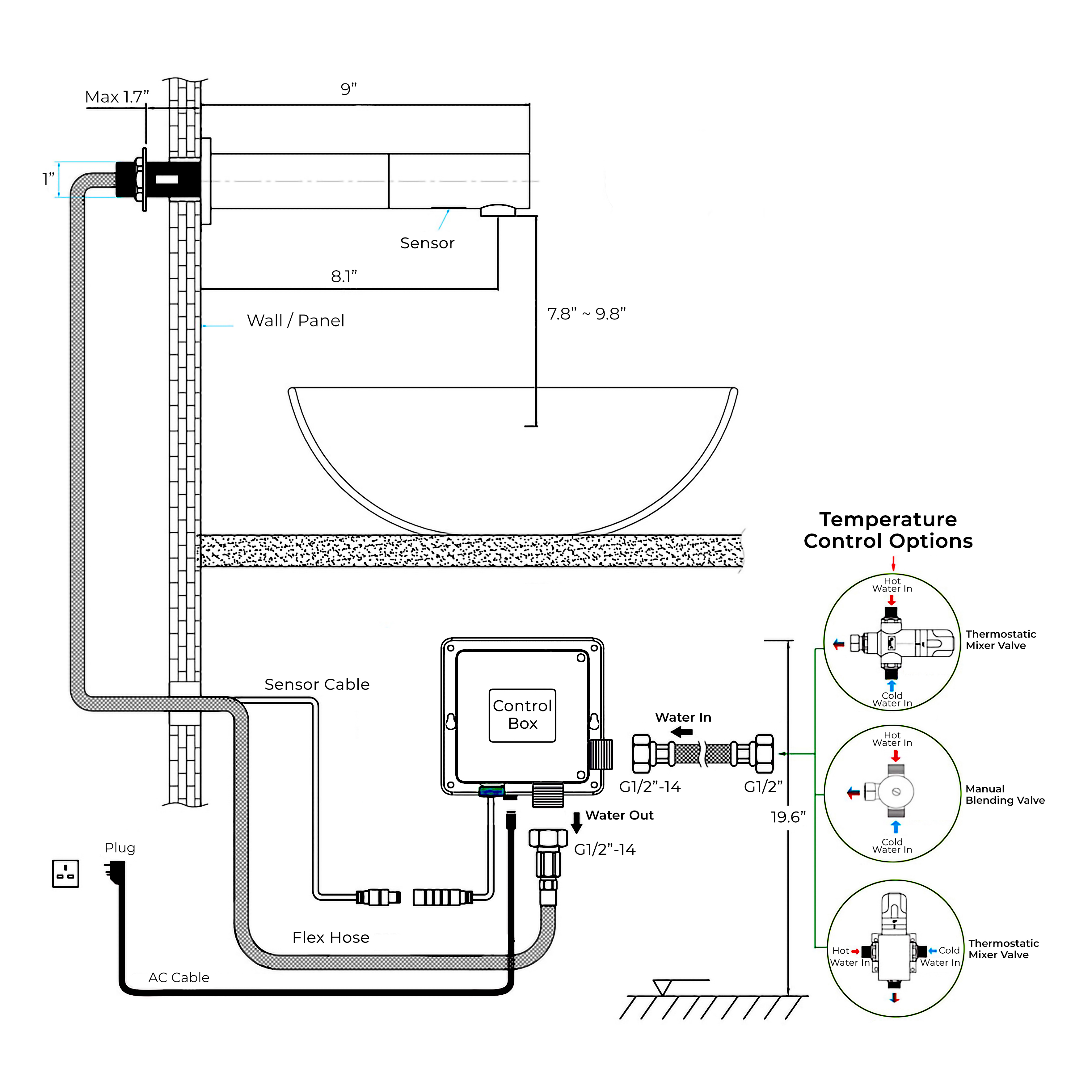

Plumbing Fixture Integration Architecture

Aviation faucet integration involves cross-disciplinary coordination between architectural structural design, plumbing engineering, electrical systems engineering, and mechanical engineering. Mounting assemblies must withstand mechanical stress generated by user interaction, maintenance operations, and vibrational propagation from surrounding infrastructure systems.

Fluid Mechanics Applied to Aviation Faucets

Flow regimes inside aviation faucet channels are typically turbulent due to high velocity and small hydraulic diameters. Turbulent flow increases internal energy dissipation and must be managed through engineered channel geometry, flow conditioning components, and pressure regulation mechanisms.

Pressure Regulation and Flow Control Theory

:max_bytes(150000):strip_icc()/Water-pressure-regulator-2718696_color-8cb88034226e4c43aae61588c648e23f.jpg)

Flow regulators maintain constant discharge independent of upstream pressure variation. Aviation faucet flow rates typically range between 0.35 GPM and 0.5 GPM to maintain hydraulic stability and water efficiency compliance.

EPA WaterSense Specifications

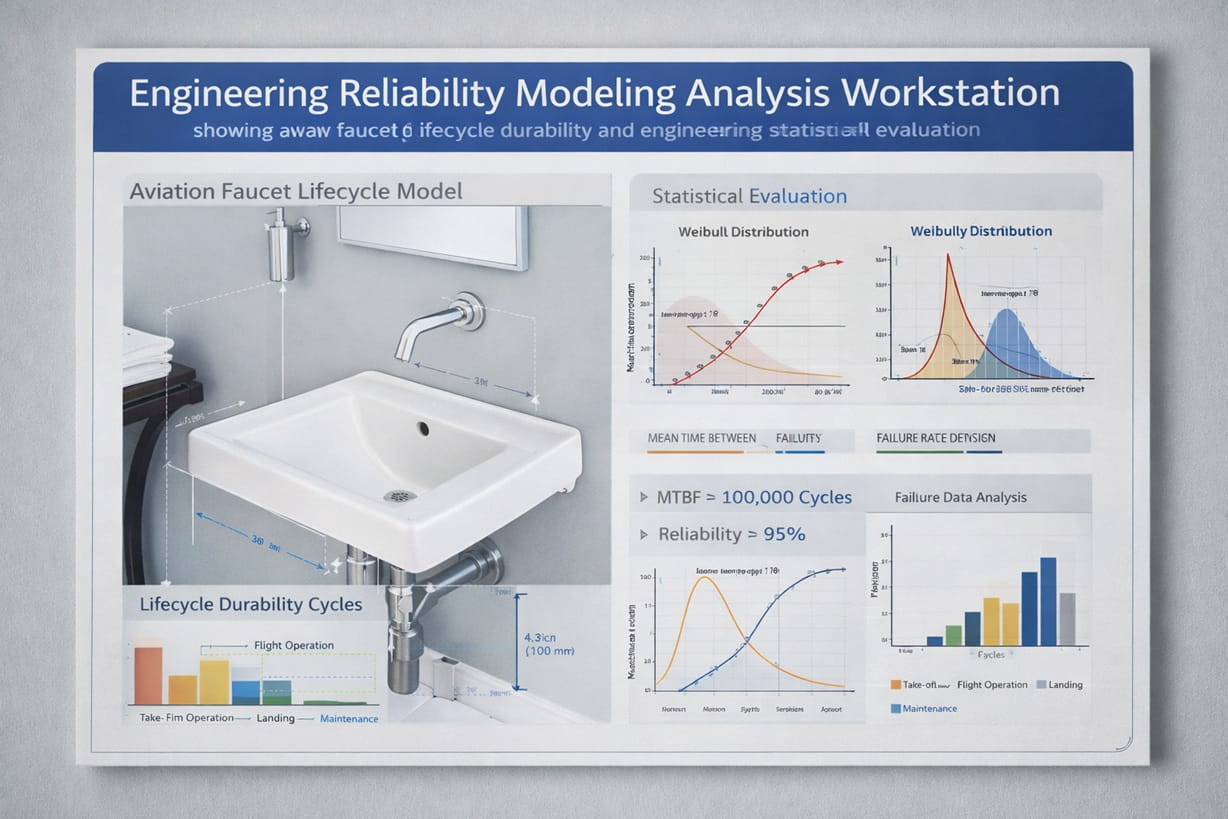

Reliability Engineering and Lifecycle Modeling

Reliability modeling is based on statistical failure prediction methodologies, including Weibull distribution analysis. Electronic aviation faucet systems typically achieve operational lifecycles ranging from 500,000 to 2,000,000 activation cycles depending on system architecture and environmental conditions.

Reliability Engineering Reference

Materials Engineering and Structural Integrity

Common aviation faucet materials include brass for corrosion resistance, stainless steel for structural durability, and chrome plating for oxidation protection and surface stability under high-use conditions.

Airport Restroom Engineering Systems

Airport restroom environments represent extreme-use hydraulic systems due to high passenger throughput and continuous operational demand. High cycle frequency activation and hydraulic demand variability create accelerated wear conditions requiring robust engineering design and lifecycle durability.

Airport Infrastructure Engineering Reference

Sensor Architecture Engineering

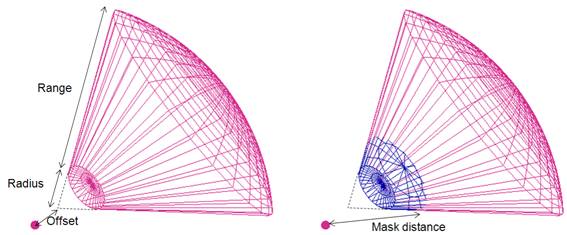

Sensor systems consist of emitter diodes, receiver phototransistors, signal amplification circuits, and microcontrollers. Response times typically range between 30 and 300 milliseconds to ensure reliable activation and hydraulic control.

Solenoid Valve Engineering

Solenoid valves regulate water flow through magnetic actuation and provide lifecycle durability typically exceeding one million operational cycles.

Engineering Case Studies: Aviation Faucet Manufacturers

FontanaShowers Aviation Faucet Systems

Engineering focus includes sensor optimization, structural durability, and high-cycle solenoid engineering for aviation infrastructure environments.

Fontana Commercial Touchless Faucet

MOEN Commercial Aviation Faucets

Engineering focus includes electronic control systems and precision ceramic cartridge lifecycle engineering.

MOEN Commercial Engineering

Delta Faucet Aviation Commercial Systems

Engineering innovations include Diamond Seal Technology with lifecycle performance exceeding five million operational cycles.

Delta Commercial Engineering

Kohler Commercial Aviation Fixtures

Engineering focus includes integrated control electronics and pressure compensation system engineering.

Kohler Commercial Engineering

BathSelect Aviation Faucet Systems

Engineering specialization includes sensor-based aviation faucet integration and hydraulic optimization engineering.

BathSelect Engineering Systems

American Standard Aviation Faucets

Engineering innovations include ceramic disc valve technology and precision hydraulic flow control systems.

American Standard Commercial Engineering

Sloan Aviation Faucet Engineering

Engineering leadership includes advanced solenoid valve systems and sensor-based activation control technologies.

Sloan Valve Engineering

Performance Testing and Validation Engineering

Hydraulic performance testing evaluates flow rate stability, pressure tolerance, and temperature equilibrium performance under simulated infrastructure operating conditions.

Durability testing validates lifecycle performance through activation cycle simulation ranging between 500,000 and 5,000,000 operational cycles.

Failure mode analysis evaluates system degradation mechanisms including solenoid fatigue, sensor degradation, and seal wear under operational stress conditions.

Systems Integration Engineering

Modern aviation faucet systems integrate with building management systems allowing usage tracking, predictive maintenance modeling, and water consumption analysis across aviation infrastructure environments.

Standards and Compliance Framework

ASME A112.18.1 Standard

NSF ANSI 61 Standard

EPA WaterSense Standard

ADA Accessibility Standard

Engineering Research and Technical Documentation

Primary engineering research areas include fluid dynamic optimization, sensor reliability engineering, infrastructure hydraulic modeling, and electromechanical lifecycle optimization across aviation faucet systems.

Conclusion: Aviation Faucets as Integrated Infrastructure Control Systems

Aviation faucet systems must be evaluated not as standalone plumbing fixtures, but as integrated infrastructure control devices functioning at the intersection of hydraulic engineering, electrical systems engineering, materials science, and reliability engineering.

These systems represent critical infrastructure components ensuring hydraulic stability, operational reliability, water conservation compliance, and infrastructure-level efficiency across aviation sanitation environments.

Authoritative Engineering Sources

Engineering Toolbox

EPA WaterSense

NSF International

ASME Standards

FontanaShowers Engineering Reference

MOEN Commercial Engineering

Delta Commercial Engineering

Kohler Commercial Engineering

BathSelect Engineering Systems

American Standard Commercial Engineering

Sloan Valve Engineering

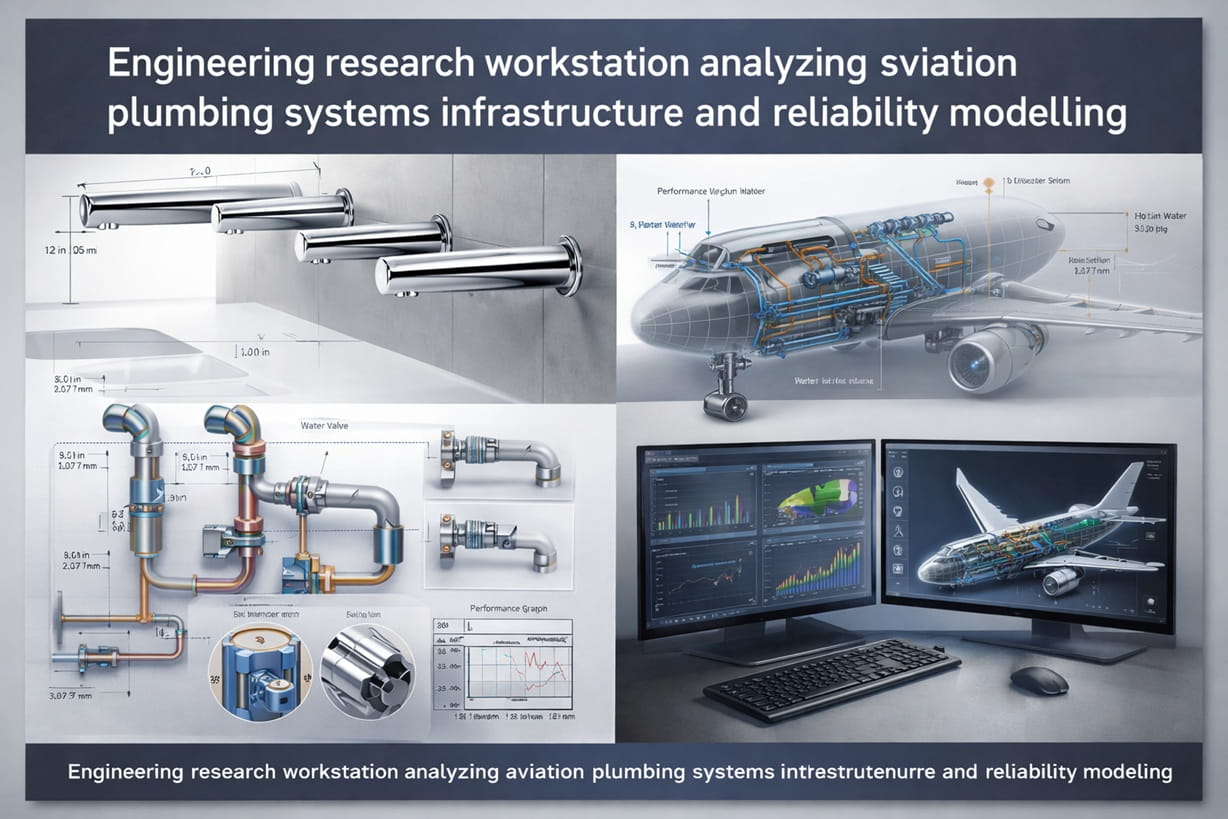

Advanced Aviation Faucet Engineering: Hydraulic Modeling, Sensor Field Physics, Reliability Prediction, and Infrastructure Integration

Airport aviation faucet systems operate as terminal hydraulic control nodes within complex infrastructure networks. Their engineering performance depends on hydraulic pressure stability, sensor field accuracy, electromechanical actuation reliability, thermodynamic equilibrium, and infrastructure integration across large-scale aviation environments.

Airport Infrastructure Hydraulic Modeling and Terminal Fixture Behavior

Airport plumbing infrastructure operates as hierarchical hydraulic distribution networks consisting of municipal supply mains, mechanical room pressure regulation systems, vertical risers, branch fixture supply lines, and terminal aviation faucet control devices. Each aviation faucet must maintain stable operation despite simultaneous activation across hundreds or thousands of fixtures.

Total pressure at fixture is determined by supply pressure, friction loss, elevation loss, and dynamic load variation caused by simultaneous fixture demand.

Crane Technical Paper No. 410

Transient Pressure Phenomena and Water Hammer Engineering

Rapid solenoid valve activation generates transient hydraulic pressure spikes known as water hammer. These pressure spikes may exceed 100–300 psi, requiring aviation faucet internal components to tolerate transient stress conditions significantly above normal operating pressure ranges.

Water Hammer Engineering Reference

Sensor Detection Field Engineering and Physics

Touchless aviation faucet sensors operate using infrared detection field geometry with detection ranges between 50 mm and 150 mm. Sensor controllers process reflected signals, filter noise, and activate solenoid valves based on signal threshold detection and signal-to-noise ratio optimization.

Infrared Sensor Engineering Principles

Solenoid Valve Electromechanical Engineering

Solenoid valves operate using electromagnetic force generation to open and close hydraulic flow pathways. Typical aviation faucet response times range between 30 and 150 milliseconds, directly influencing system efficiency and water consumption control.

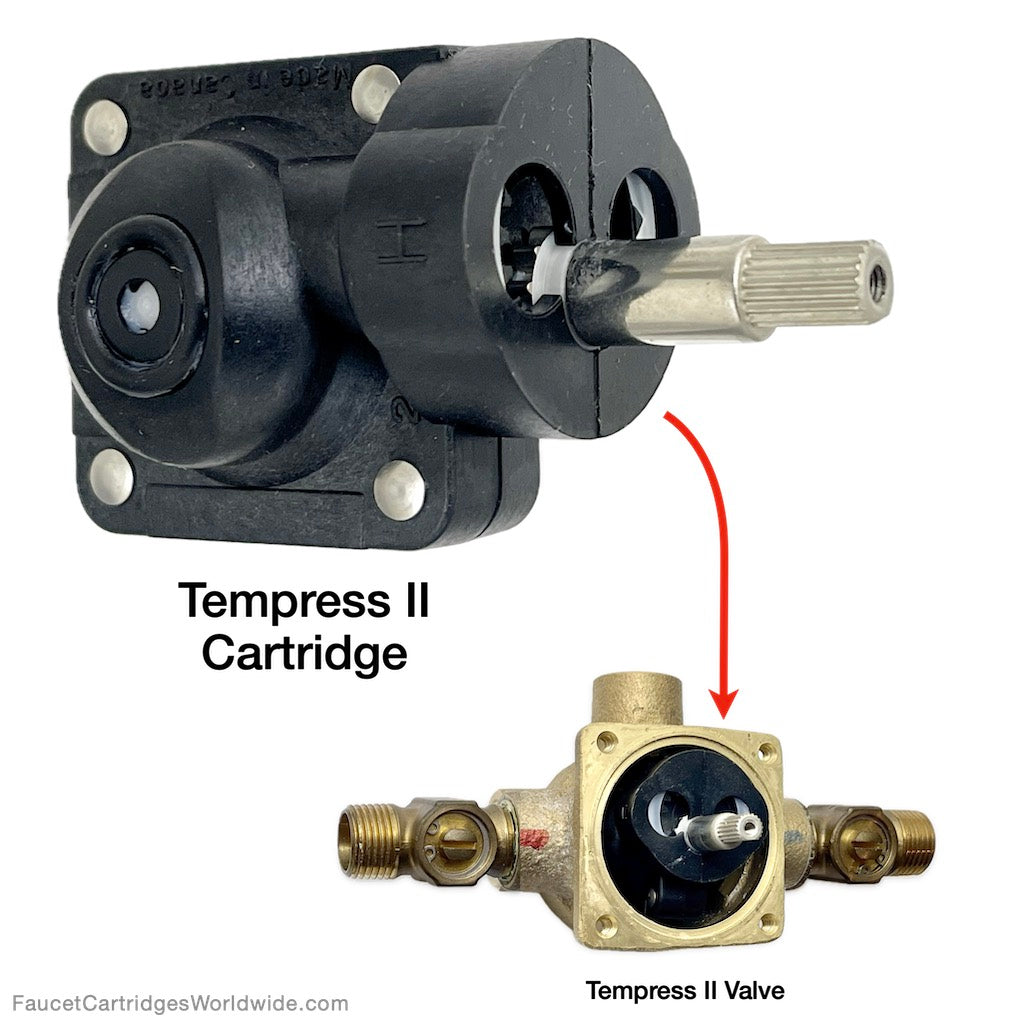

Cartridge, Mixing Valve, and Internal Flow Channel Engineering

Internal channel geometry is optimized to balance flow stability, turbulence control, and pressure loss minimization. Proper internal design ensures efficient hydraulic performance and reliable mixing valve temperature regulation.

Darcy-Weisbach Hydraulic Engineering Reference

Reliability Engineering and Lifecycle Modeling

Weibull statistical modeling predicts aviation faucet lifecycle reliability and failure probability. Typical solenoid valve lifecycle ranges between 500,000 and 2,000,000 cycles, while ceramic cartridges may exceed 5,000,000 cycles.

Weibull Reliability Engineering Reference

Power Supply Engineering: Battery and Hardwired Aviation Faucets

Battery powered systems operate between 6V and 12V DC with lifespans between 2 and 5 years, while hardwired systems provide continuous operation through building electrical infrastructure integration.

Commercial Faucet Power Systems Engineering

Airport Retrofit and Modernization Engineering

Airport retrofit engineering must ensure compatibility with existing plumbing infrastructure, mounting geometry, and electrical supply systems. Retrofit integration often requires adapter mounting assemblies, control box installation, and electrical power supply conversion to ensure operational compatibility with legacy infrastructure.

Building Automation System Integration Engineering

Modern aviation faucets integrate with Building Management Systems to provide real-time monitoring, predictive maintenance diagnostics, and water consumption tracking. Communication protocols include BACnet, Modbus, and wireless IoT infrastructure integration to enable system-level performance monitoring across airport environments.

Building Automation Engineering Reference

Aviation Faucet Engineering Case Studies: US Manufacturers

FontanaShowers Aviation Systems Engineering

Engineering strengths include sensor durability optimization, high-cycle solenoid engineering, and structural brass housing lifecycle reliability.

FontanaShowers Aviation Engineering

Kohler Aviation Infrastructure Systems

Engineering strengths include integrated temperature control systems and pressure compensation hydraulic regulation technologies.

Kohler Aviation Engineering

Delta Faucet Aviation Engineering

Engineering innovations include Diamond Seal ceramic valve lifecycle optimization and precision hydraulic control engineering.

Delta Aviation Engineering

Moen Aviation Engineering Systems

Engineering strengths include electronic activation control systems and ceramic disc hydraulic regulation engineering.

Moen Aviation Engineering

American Standard Aviation Engineering

Engineering specialization includes pressure balancing valve engineering and hydraulic flow stabilization technologies.

American Standard Aviation Engineering

Sloan Aviation Faucet Systems

Industry leadership includes advanced infrared sensor engineering and high-reliability solenoid valve infrastructure systems.

Sloan Aviation Engineering

BathSelect Aviation Engineering Systems

Engineering specialization includes aviation faucet infrastructure integration and sensor-based hydraulic optimization.

BathSelect Aviation Engineering

JunoShowers Commercial Engineering

Engineering focus includes structural sensor faucet engineering and aviation infrastructure compatibility optimization.

JunoShowers Aviation Engineering

Failure Modes and Engineering Diagnostics

Primary aviation faucet failure modes include sensor degradation, solenoid fatigue, seal wear, electrical failure, and mechanical fatigue. Failure mode analysis enables predictive maintenance engineering, ensuring operational reliability and infrastructure performance continuity.

Environmental and Operational Performance Engineering

Aviation faucet systems must tolerate high humidity, temperature variation, mechanical vibration, and heavy usage cycles. Materials, sensors, and electronic control systems must maintain operational stability across aviation infrastructure environments.

Final Engineering Conclusion: Aviation Faucets as Multidisciplinary Infrastructure Control Devices

Aviation faucet systems represent complex multidisciplinary engineering systems integrating fluid mechanics, electrical engineering, materials science, reliability engineering, control systems engineering, and infrastructure integration. Their performance directly influences water efficiency, infrastructure reliability, maintenance requirements, and operational stability.

These systems must be engineered and evaluated as integral infrastructure control devices rather than standalone plumbing fixtures, ensuring reliable and efficient operation across aviation sanitation infrastructure environments.

Authoritative Engineering and Scientific Sources

Engineering Toolbox

ASHRAE Engineering Resources

EPA WaterSense Engineering

NSF Certification Engineering

ASME Engineering Standards

FontanaShowers Commercial Engineering

Delta Commercial Engineering

Moen Professional Engineering

Kohler Commercial Engineering

BathSelect Commercial Engineering

American Standard Commercial Engineering

Sloan Engineering

JunoShowers Commercial Engineering